About Us

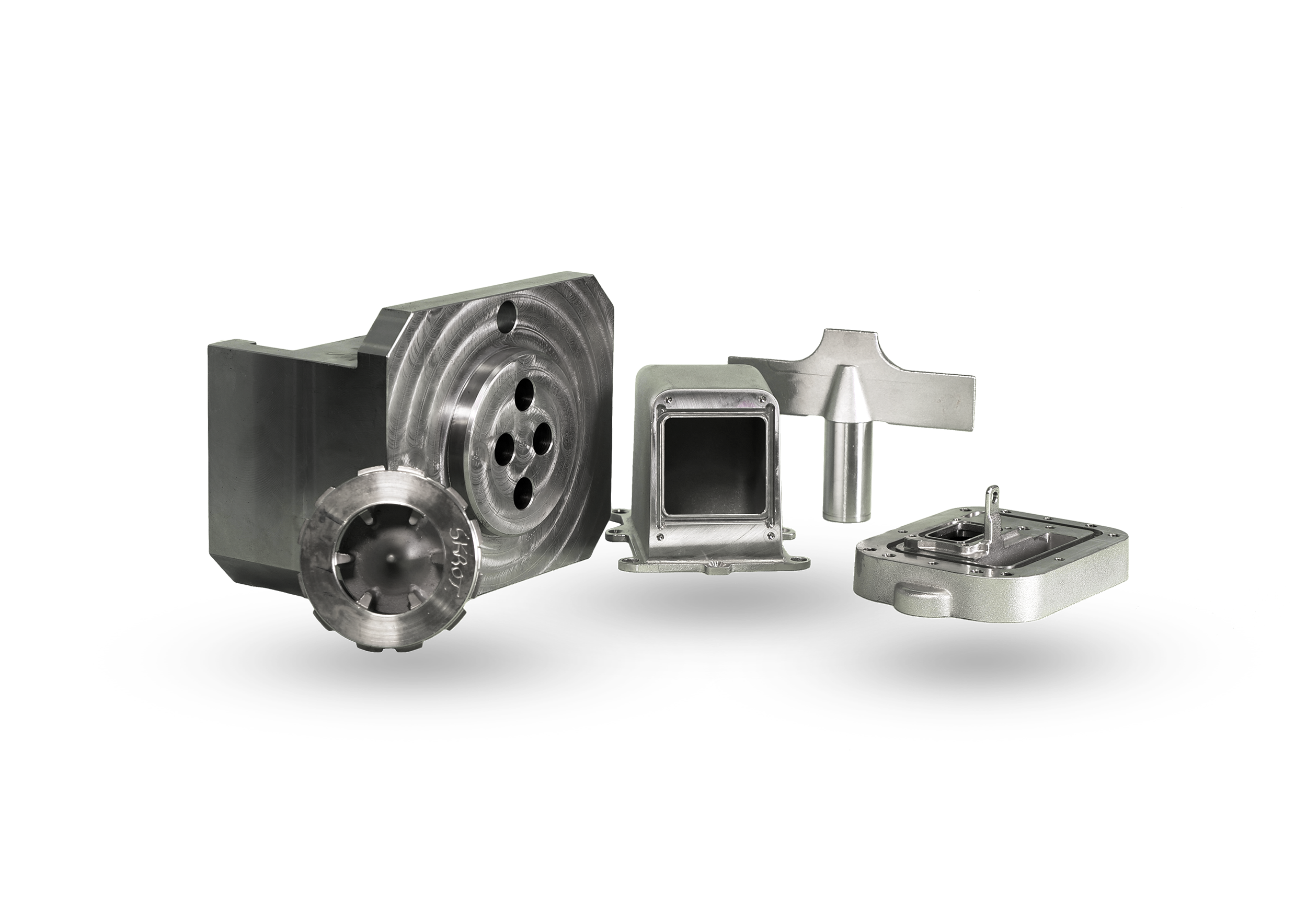

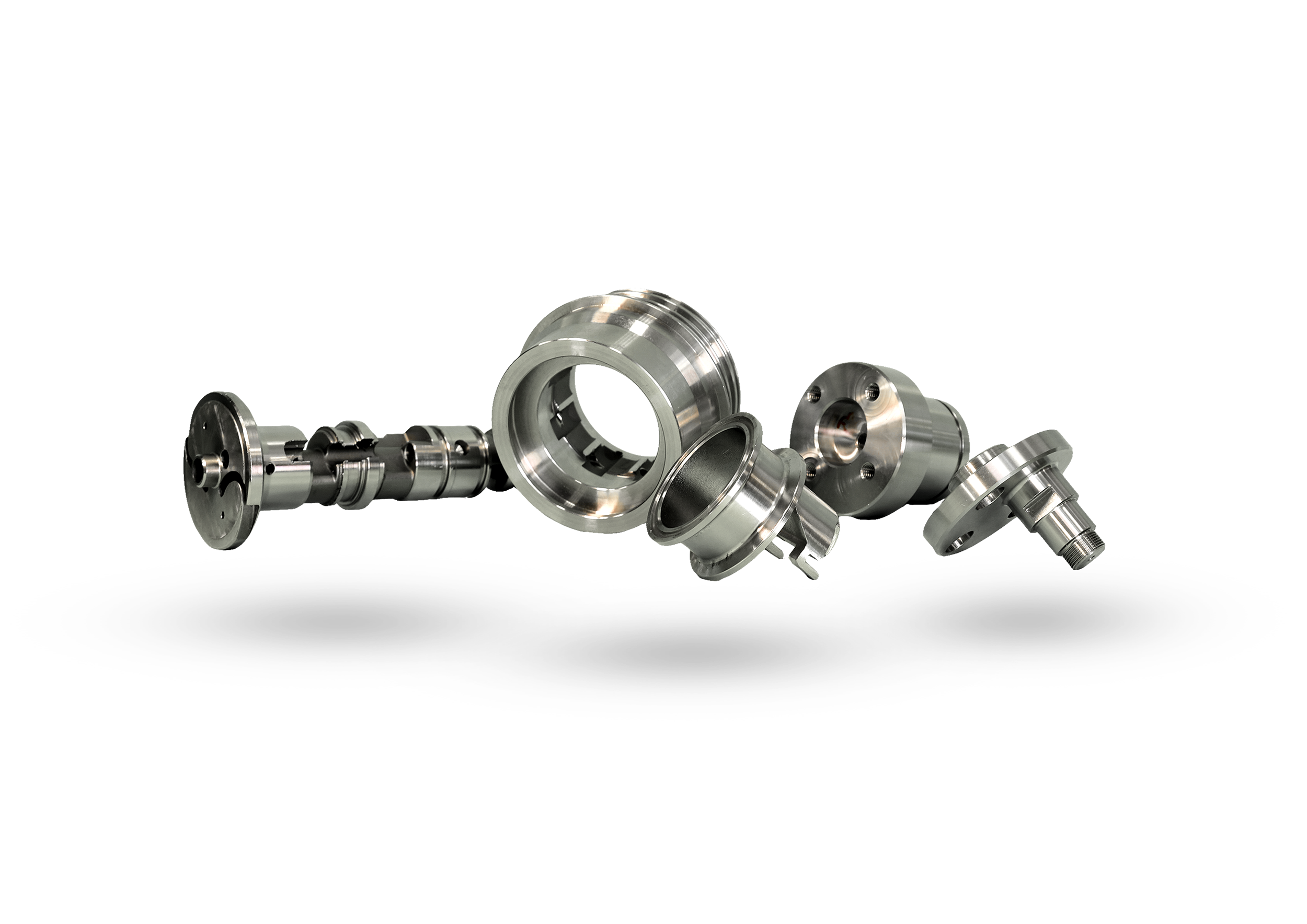

GIAB Machining OÜ is your reliable partner for high quality manufacturing services. We deliver to our customers machined parts and subassemblies as well as investment casted parts. Our company was established in 2006 as subsidiary of Swedish company TPC Components AB.

TPC Components AB is an investment casting company and our strategic partner. We offer our customers casted and machined parts. Movie about our production:

From beginning of 2018 our company belongs to GIAB Eesti OÜ which is 100% owned by Gabrielsson Invest AB.

About Us

GIAB Machining OÜ is your reliable partner for high quality manufacturing services. We deliver to our customers machined parts and subassemblies as well as investment casted parts. Our company was established in 2006 as subsidiary of Swedish company TPC Components AB.

TPC Components AB is an investment casting company and our strategic partner. We offer our customers casted and machined parts. Movie about our production: www.tpcab.se/eng/movie.html.

From beginning of 2018 our company belongs to GIAB Eesti OÜ which is 100% owned by Gabrielsson Invest AB.

About Us

GIAB Machining OÜ is your reliable partner for high quality manufacturing services. We deliver to our customers machined parts and subassemblies as well as investment casted parts. Our company was established in 2006 as subsidiary of Swedish company TPC Components AB.

TPC Components AB is an investment casting company and our strategic partner. We offer our customers casted and machined parts. Movie about our production:

From beginning of 2018 our company belongs to GIAB Eesti OÜ which is 100% owned by Gabrielsson Invest AB.

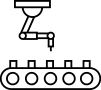

Market Segments

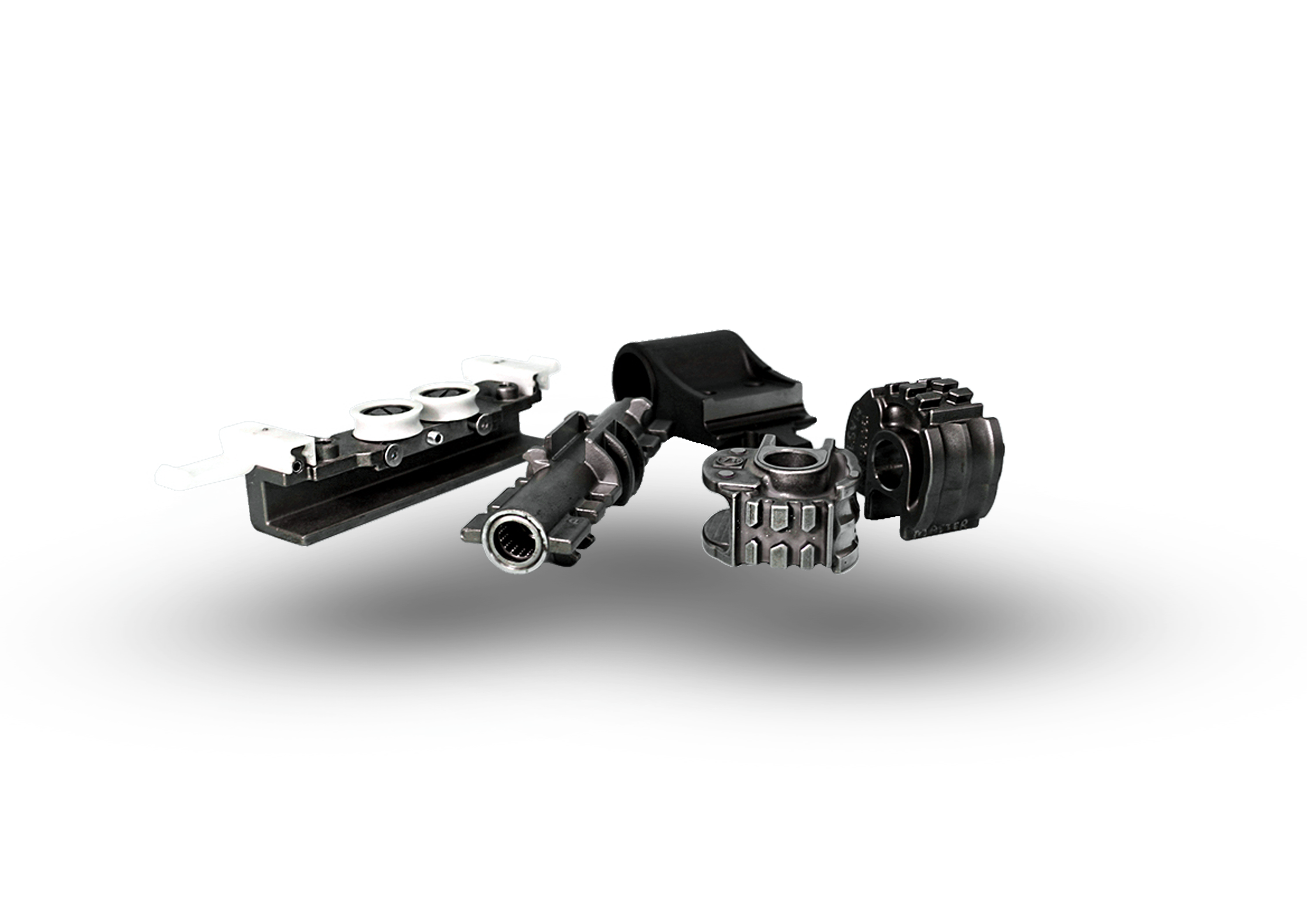

Industrial equipment and machine building

Our details are used in different machines from sewing, mining and lifting machines to food industry.

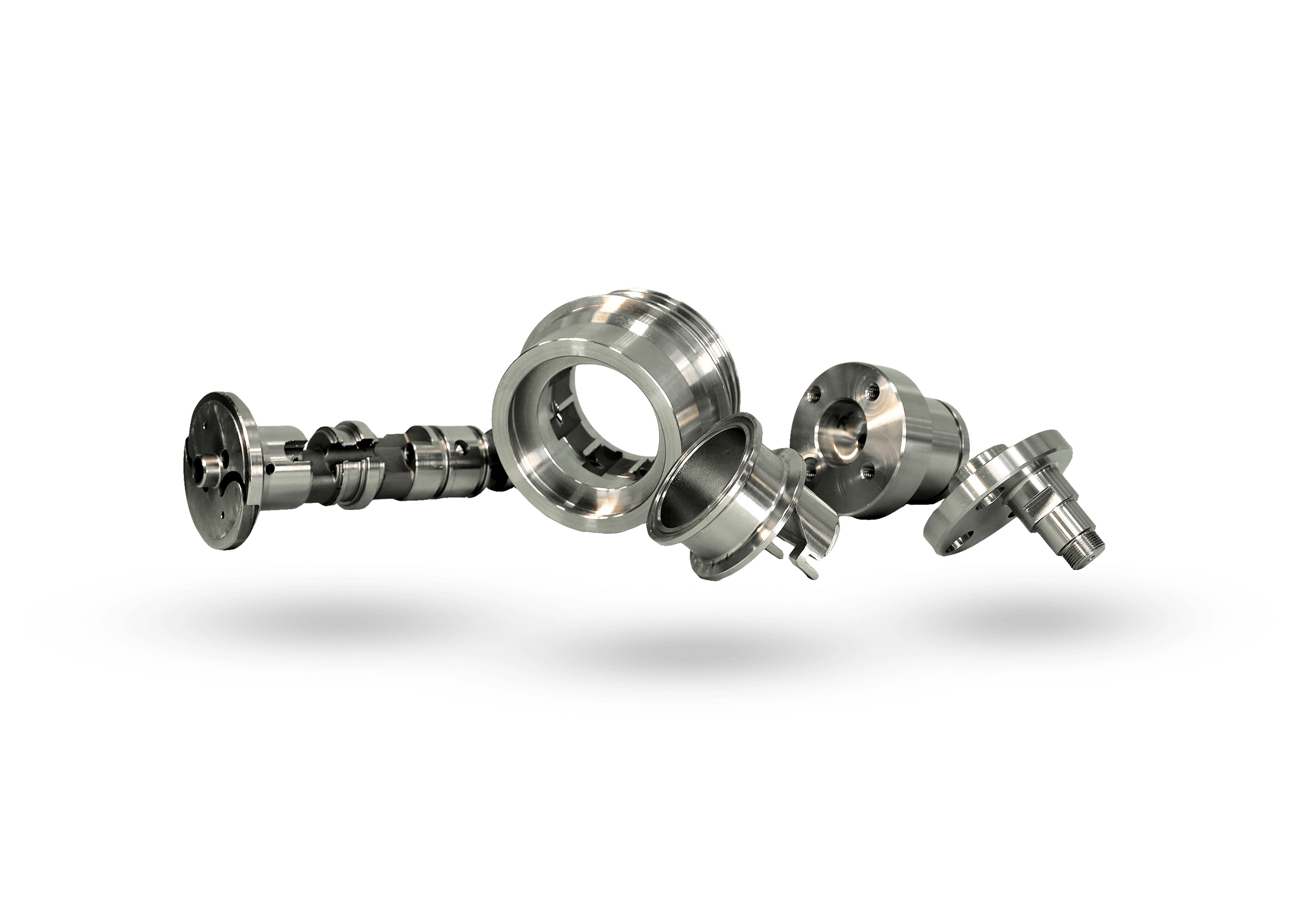

Energy

Our parts are used in gas tourbines and in many another equimpment.

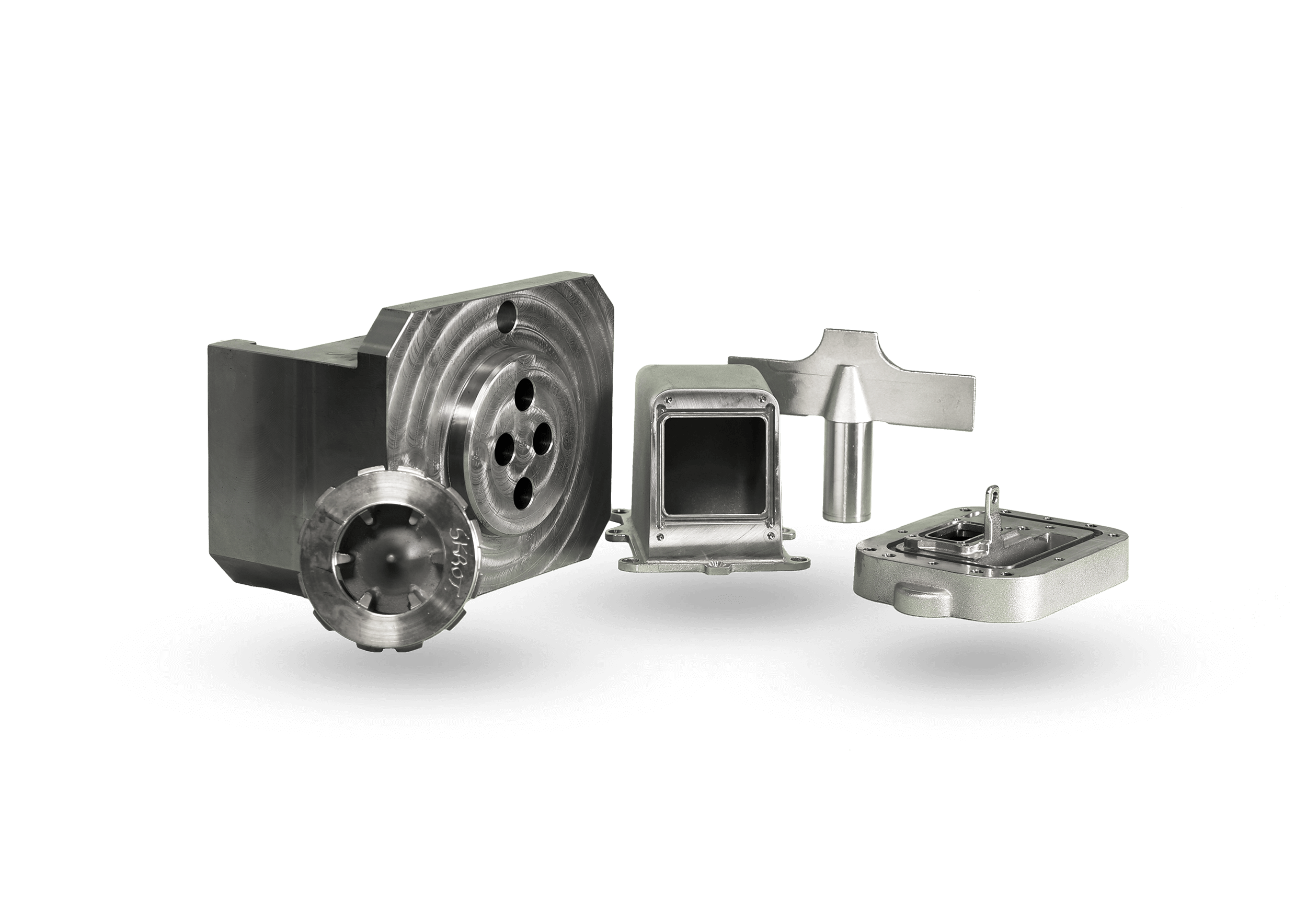

Automotive

Together with our strategic partner, TPC Components AB, we are producing group B spare parts for automotive industry. Our parts are used in Porsche, BMW, Volvo and Scania.

Industrial equipment and machine building

Our details are used in different machines from sewing, mining and lifting machines to food industry.

Energy

Our parts are used in gas tourbines and in many another equimpment.

Automotive

Together with our strategic partner, TPC Components AB, we are producing group B spare parts for automotive industry. Our parts are used in Porsche, BMW, Volvo and Scania.

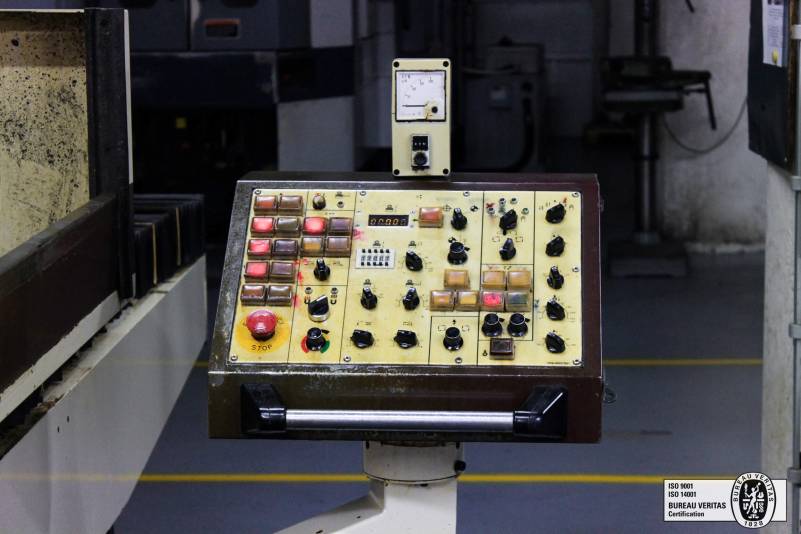

Main Technologies

Maximum dimensions for milling 500x1000mm

Maximum dimensions for milling 500x1000mm

Maximum dimensions for milling 500x1000mm

Stama MC310

Kitamura Mycenteer 3/835

Matsuura MC 1000V

Quaser MK60IIH

Mori Seiki b SH403

Mori Seiki s SH403

Mori Seiki SH40

Mori Seiki SH403 (Sw)

Mori Seiki SH5000

Mori Seiki SH4000

Mitsui Seiki HT3A

Mitsui Seiki (Sw) HU40A

Victor Vcenter 70

Victor Vcenter H400

Stama MC310

Kitamura Mycenteer 3/835

Matsuura MC 1000V

Quaser MK60IIH

Mori Seiki b SH403

Mori Seiki s SH403

Mori Seiki SH40

Mori Seiki SH403 (Sw)

Mori Seiki SH5000

Mori Seiki SH4000

Mitsui Seiki HT3A

Mitsui Seiki (Sw) HU40A

Victor Vcenter 70

Victor Vcenter H400

Maximum dimensions for turning:

Z=1000mm / D=300mm

Maximum dimensions for turning:

Z=1000mm / D=300mm

Maximum dimensions for turning:

Z=1000mm / D=300mm

Dosan Puma MX250OT

Dosan Puma VT450M-2SP

Mori Seiki SL-300 (1) AMC

Mori Seiki SL-300 (2) AMC

Mori Seiki NL25004/1250

Dosan Puma MX250OT

Dosan Puma VT450M-2SP

Mori Seiki SL-300 (1) AMC

Mori Seiki SL-300 (2) AMC

Mori Seiki NL25004/1250

Maximum dimensions for turning:

Z=1000mm / D=300mm

Tolerances up to 0,01mm

Tolerances up to 0,01mm

GRINDING

GRINDING

GRINDING

Chevalier ESG-2060TC

Chevalier ESG-2060TC

Chevalier ESG-2060TC

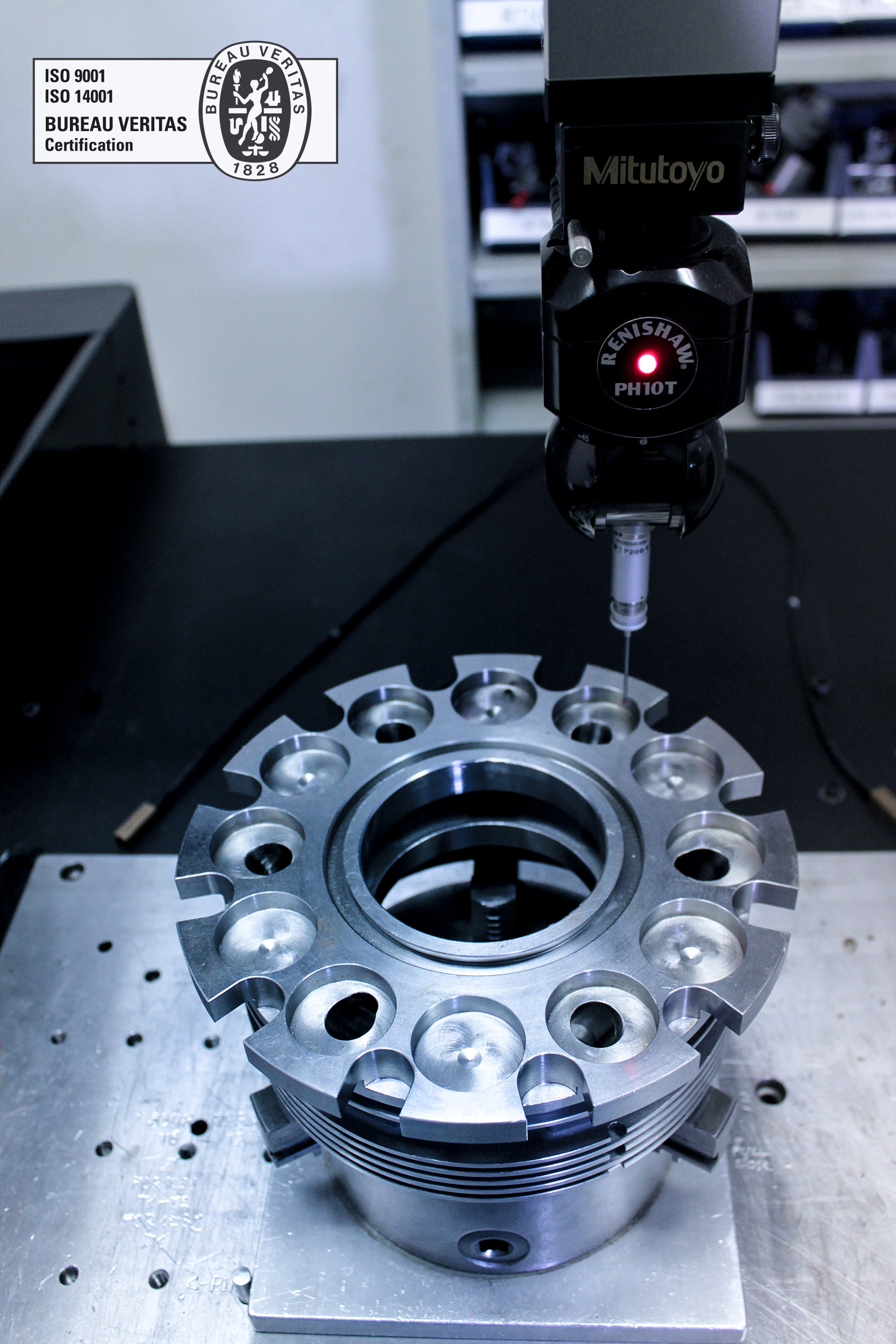

Our quality system is driven by automotive industry demands.

We have implemented SPC, 8D, A3 and also we are using some Six Sigma princips.

Management system is sertified by Bureau Veritas according to:

ISO 9001 – 2015

ISO 14001 – 2015

Our quality system is driven by automotive industry demands.

We have implemented SPC, 8D, A3 and also we are using some Six Sigma princips.

Management system is sertified by Bureau Veritas according to:

ISO 9001 – 2015

ISO 14001 – 2015

Maximum dimensions for milling 500x1000mm

Maximum dimensions for milling 500x1000mm

Maximum dimensions for milling 500x1000mm

Stama MC310

Kitamura Mycenteer 3/835

Matsuura MC 1000V

Quaser MK60IIH

Mori Seiki b SH403

Mori Seiki s SH403

Mori Seiki SH40

Mori Seiki SH403 (Sw)

Mori Seiki SH5000

Mori Seiki SH4000

Mitsui Seiki HT3A

Mitsui Seiki (Sw) HU40A

Victor Vcenter 70

Victor Vcenter H400

Stama MC310

Kitamura Mycenteer 3/835

Matsuura MC 1000V

Quaser MK60IIH

Mori Seiki b SH403

Mori Seiki s SH403

Mori Seiki SH40

Mori Seiki SH403 (Sw)

Mori Seiki SH5000

Mori Seiki SH4000

Mitsui Seiki HT3A

Mitsui Seiki (Sw) HU40A

Victor Vcenter 70

Victor Vcenter H400

Kitamura Mycenteer 3/835

Matsuura MC 1000V

Quaser MK60IIH

Mori Seiki b SH403

Mori Seiki s SH403

Mori Seiki SH40

Mori Seiki SH403 (Sw)

Mori Seiki SH5000

Mori Seiki SH4000

Mitsui Seiki HT3A

Mitsui Seiki (Sw) HU40A

Victor Vcenter 70

Victor Vcenter H400

Maximum dimensions for turning:

Z=1000mm / D=300mm

Maximum dimensions for turning:

Z=1000mm / D=300mm

Maximum dimensions for turning: Z=1000mm / D=300mm

Tolerances up to 0,01mm

Tolerances up to 0,01mm

Tolerances up to 0,01mm

Dosan Puma MX250OT

Dosan Puma VT450M-2SP

Mori Seiki SL-300 (1) AMC

Mori Seiki SL-300 (2) AMC

Mori Seiki NL25004/1250

Dosan Puma MX250OT

Dosan Puma VT450M-2SP

Mori Seiki SL-300 (1) AMC

Mori Seiki SL-300 (2) AMC

Mori Seiki NL25004/1250

Dosan Puma MX250OT

Dosan Puma VT450M-2SP

Mori Seiki SL-300 (1) AMC

Mori Seiki SL-300 (2) AMC

Mori Seiki NL25004/1250

Assembly

Chevalier ESG-2060TC

Chevalier ESG-2060TC

Chevalier ESG-2060TC

GRINDING

GRINDING

GRINDING

Our quality system is driven by automotive industry demands.

We have implemented SPC, 8D, A3 and also we are using some Six Sigma princips.

Management system is sertified by Bureau Veritas according to:

ISO 9001 – 2015

ISO 14001 – 2015

Our quality system is driven by automotive industry demands.

We have implemented SPC, 8D, A3 and also we are using some Six Sigma princips.

Management system is sertified by Bureau Veritas according to:

ISO 9001 – 2015

ISO 14001 – 2015

Our quality system is driven by automotive industry demands.

We have implemented SPC, 8D, A3 and also we are using some Six Sigma princips. Management system is sertified by Bureau Veritas according to:

ISO 9001 – 2015

ISO 14001 – 2015

Technologies

– Cutting Saw

– Grinding

– Trumbling

– Welding

– Sand Blastering

– Hydraulic Press

– 2 Grinding Robots

– Quality measurement equipment (Mitutoyo Apex C)

– Cutting Saw

– Grinding

– Trumbling

– Welding

– Sand Blastering

– Hydraulic Press

– 2 Grinding Robots

– Quality measurement equipment (Mitutoyo Apex C)

Supporting Technologies

- Cutting Saw

- Grinding

- Trumbling

- Welding

- Sand Blastering

- Hydraulic Press

- 2 Grinding Robots

- Quality measurement equipment (Mitutoyo Apex C)

Contact Us

MADIS

MÄDAMÜRK

General Manager

madis.madamyrk@giab.ee

+372 511 9650

IGOR

SMOLENTSEV

Quality Manager

igor.smolentsev@giab.ee

+372 5332 8874

JEKATERINA

DUBINKO

Planner/ Logistics

jekaterina.dubinko@giab.ee

+372 5385 7273

MARIA

BORISSOVA

Accountant

maria.borissova@giab.ee

+372 5887 7893

MADIS

MÄDAMÜRK

General Manager

madis.madamyrk@giab.ee

+372 511 9650

IGOR

SMOLENTSEV

Quality Manager

igor.smolentsev@giab.ee

+372 5332 8874

KIRILL

TEPLYKH

Production Manager

kirill.teplykh@giab.ee

+372 5302 6617

JEKATERINA

DUBINKO

Planner/ Logistics

jekaterina.dubinko@giab.ee

+372 5385 7273

MARIA

BORISSOVA

Accountant

maria.borissova@giab.ee

+372 5887 7893

Kulgu 8, 20104 Narva, Estonia

Kulgu 8, 20104 Narva, Estonia